Some more intriguing photo’s from Chris

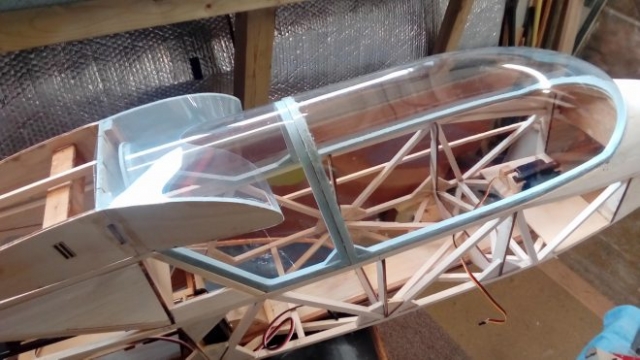

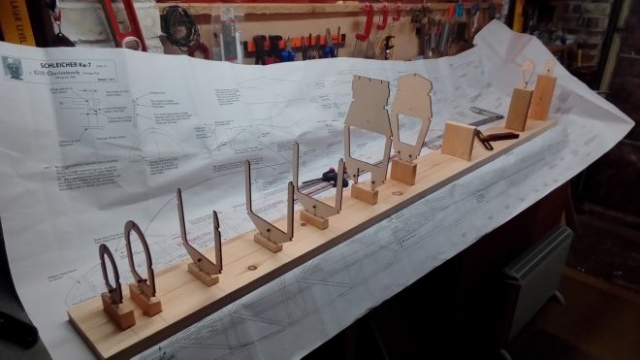

A bit more progress: The full size had a all flying tailplane, I was going to do the same, but with such a small bearing width 19mm, and a tailplane at 900mm, I couldn’t stop the tailplane wobbling, at the tip, well not enough for me.

Not a problem, fix the tailplane and have a elevator, so I measured and cut out the elevator, problem no2; the elevator was going to be top hinged, 15mm at the center, tapering to 3mm at the tips. It gave a nice curve, OK when on the center line, but when you try to go down or up, the tips want to move away from the tailplane.

Plan C; split the elevator in the center, and operate with 2 servos, or make a new elevator with the top surface level, went with a split elevator.

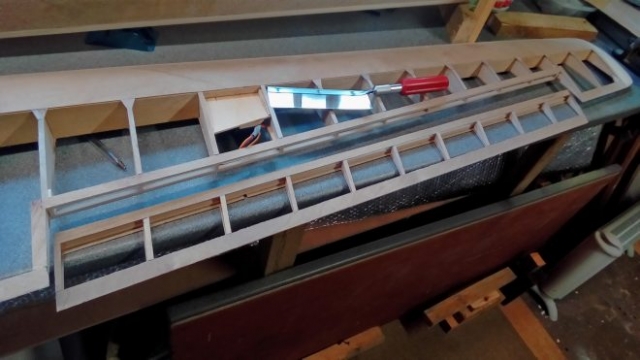

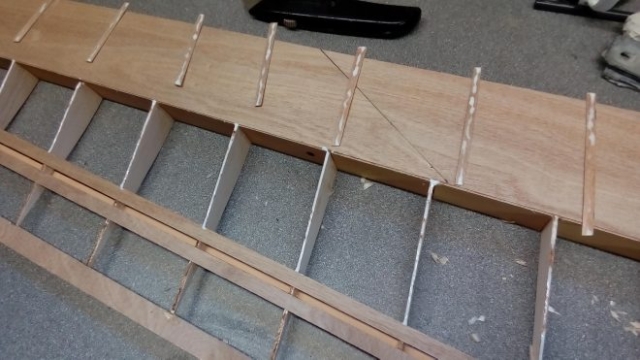

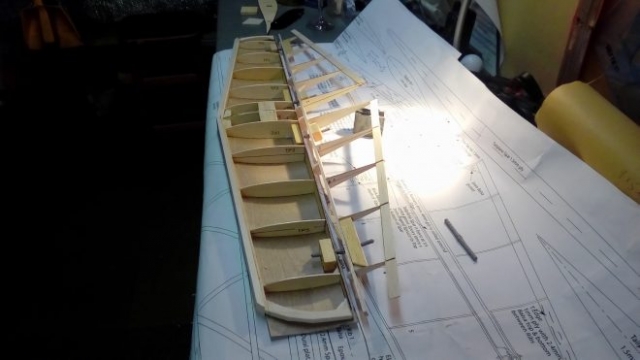

I have made the wing spars, 2mm ply with carbon on one side, a center foam core, then carbon toes laid on top of the foam, top & bottom. The spar was then glued into the foam cores, balsa was then glued on top of the toes, so that this could be sanded down to the wing profile. Glass cloth was placed on the foam with epoxy, obechi verneer, placed on top, then epoxy brushed on top of the veneer, then tissue paper placed on the wet epoxy, mylar sheet then placed on top, and the whole lot placed in a vacbag.

Chris

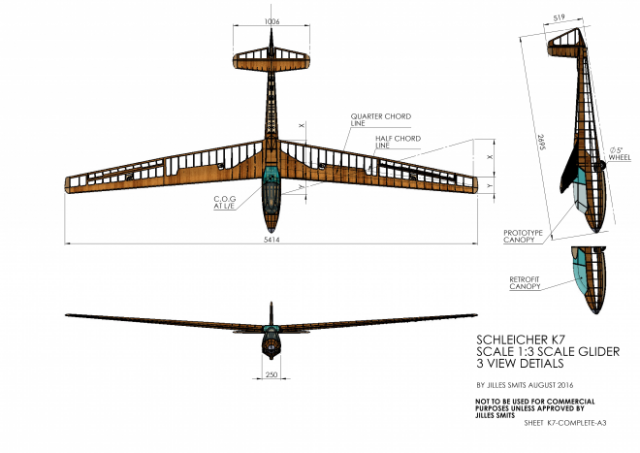

Check out the photos here