Hello DSSC.

I thought you might be interested to see my new slope soarer design which carries on from where I left the hobby in 1980. The repeated design/build/fly/crash, design/build/fly… cycle which dominated much of my spare time in the 70’s, culminated in this rugged 2-channel model I still have 40 years later.

My own design from the seventies

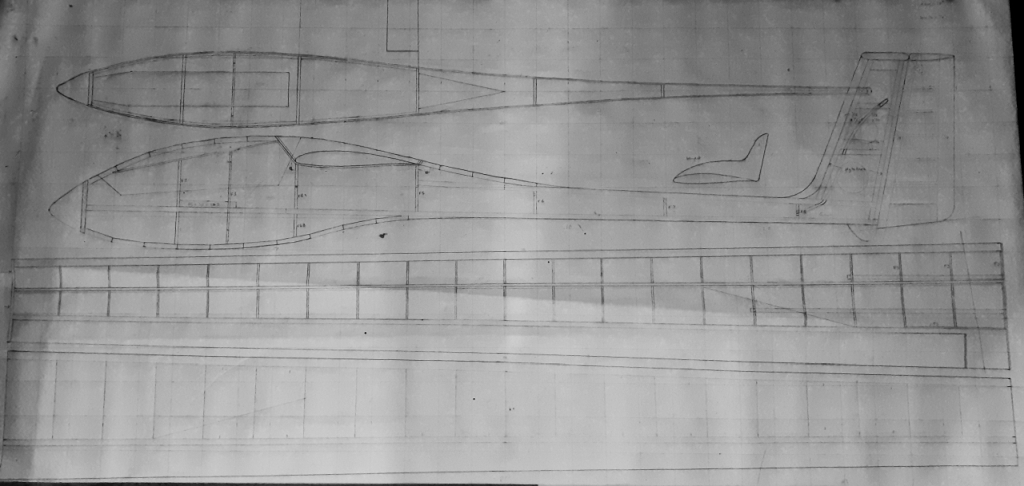

My new design uses the same boxy fuselage construction – full length thin ply sides, soft 1/4″ balsa top and bottom – but instead of 1/16″ all-sheeted wings I’ve copied the open-frame Kloudrider wing construction but with a semi-symmetrical section and higher aspect ratio.

I’ve designed things with ailerons in the past but not flaps. I rather fancied doing both this time but I’ve never really understood why control surface movements try to make different parts of the wing behave in different ways at the same time. So, I decided to go for full length flaperons (which I’ve also never done before) and to try the old ‘sliding servo’ way of mixing the controls which I heard about in the 70’s but never tried.

(By now you’ll have worked out that I’m some kind of weird old-timer who doesn’t want a foamie, doesn’t like programming, but does like a challenge!). “No wonder they used to crash” I hear you say.

The fuselage shape is influenced by the ASW 15 and 17 but I also like the way the 28 is concave on the underside of the fuselage. I also fancied having a go at a T-tail as I’ve never done one of those either. Oh and those little winglet things too – they look like fun. I decided to make the front end pretty big so I can get all four servos in and still have plenty of room for my fingers which don’t work as well as they used to. Anyway, that’s enough waffle for now. Here’s my hand-drawn plan which I’ve already deviated from slightly… (more in the next post):

My new design

David